WorkPrinter-16

HD Instructions

For use with a PC or Mac using the SyncMouse

NOTE: If international on 220VAC

at 50 cycles, you will need a

transformer that outputs 110-120VAC

at 250 watts.

You will need a Mac or PC with three internal drives.

One drive should be your system drive and the other two should be set up

in a Raid-0 drive array. Failure to use an internal Raid-0 array can result

in a loss of sync on the captured file. Drives should be ATA or Ultra-ATA

for your Raid. SATA drives do not work well for rapid stop motion capture

due to mechanical differences in how serial drives cycle compared to parallel

drives.

For the Mac, you will need the CaptureMate software.

For the PC, you will need CineCap software.

Both are available only to MovieStuff customers that

have received their WorkPrinter units shipped directly from MovieStuff.

Please email us with the

name and email address that was on the order form used to purchase the

WorkPrinter unit and we will email you the private purchase link for either

the CineCap or CaptureMate software. To maintain your warranty and customer

support, we ask that you please do not publically post this purchase link

on the web. Thanks.

After unpackaging the

unit, place on a sturdy and stable surface.

The end with the condenser

lens should allow for a tripod to be placed

about a meter or less

from the unit with clearance enough

for the tripod legs.

The tripod should have an adjustable height via

a column and the head

should allow for seperate horizon and tilt functions.

Ball-head tripods

should be avoided.

First, install the

condenser lens.

(glass should be cleaned

with non-alcohol products and a clean, cotton cloth)

Next, connect the cables

as shown.

The white cable is

from the special sync-mouse provided.

The large multi-pin

cable is found coiled in the back of the projector.

Next, load some film

into the unit as shown and

switch on the power.

With the motor switch

"off", turn the control knob

to the play position

to close the gate.

Run the motor switch

briefly to seat the film and to proceed to a

bright, well exposed

frame.

Make sure the selector switch on the WorkPrinter is

in the middle (off) position.

Make sure that the sync mouse is the only mouse plugged

into your computer. Then turn on your computer. Make sure the camera is

mounted on a tripod (column type is best) and is level and centered in

approximate height with the condenser lens. Also, make sure that you can

see the resulting, live image on a large monitor. Using the tiny LCD monitor

on the camera will make critical adjustments tough. Use of a broadcast

underscan monitor is ideal because it will let you see the edges of the

video frame for proper cropping of the image. Consumer TV monitors do not

let you see the entire video frame, which can result in improper cropping

and unlevel images. As a substitute for an underscan monitor, you can use

the capture window of your favorite video editing program, which usually

shows about 99% of the video image.

Make sure your camera is not set to any "auto shutter"

or “steady shot” positions. At a minimum, 60th of a second speed

should be used for NTSC or 50th of a second for PAL. Higher shutter speeds

will make setting the timing on this unit easier.

NOTE: If using an HD camera in the SD mode, you will

need to set your shutter speed to 1/500th of a second or higher

to overcome the latency inherent in CMOS imaging chips.

Avoid using progressive scan or "frame mode". Just

the normal interlaced video mode is needed. Best results and best registration

is achieved if your film has been freshly cleaned and lubed with good splices

and no torn sprocket holes. Supply reels should be inspected for warpage

or anything that will impede the even feed of film from the reel. Feed

reels that bind or grab the edges of the film may cause registration problems

or even film damage. Head leader should be fairly straight without a lot

of "curl memory" that will impede proper loading.

Various films have

different frame line placements. To make minor adjustments

in the vertical positioning

of the frame, use the adjustable foot at the front of

the projector as shown.

Position the camera

about 2.5 feet from the lens. Look at the monitor

for distortion of

the image. If there is curvature of the image top and bottom

then you need to adjust

the focus knob of the projector to correct. This will make the image

go out of focus, which

is normal. Always reclaim your focus using the camera lens.

Never use the projector

focus knob to adjust focus. The projector

focus knob should

only be used to correct for distortion.

NOTE:

It should be noted that the focus can be adjusted

in two different ways: your camera and the projector. In fact, because

there is no screen, the lens of the projector, the condenser lens and the

camera lens are all working as one, big lens. Moving elements to different

positions will create different results. If you zoom in and find that you

can fill the frame but can not focus at all or evenly via the camera, set

the camera focus as best you can and then adjust the focus of the projector.

Ultimately, there is little I can tell you here about

how to set your focus as every camera is different. You will have to experiment

with your set up until you get it right. I can tell you that you should

be able to get it sharp edge to edge with no chromatic aberrations and

no distortion or pin cushion. Just remember that you have several ways

to attenuate the image by using the projector focus and camera focus in

combination. Once you feel you have achieved the desired result, zoom your

camera in to rid the image of the edges of the gate and refocus. The image

should be sharp edge to edge and corner to corner with no hot spot nor

any chromatic aberrations. If the edge of the frame goes dark when you

zoom in, just adjust the placement of the camera side to side (not panning,

but actually moving the camera) ever so slightly until you restore even

illumination.

Exposure can be adjusted

using the PRESET knob.

To begin capture,

launch your capture software and verify that you have an image

in the capture window.

Type the appropriate file information and then

place the cursor over

the capture button and leave it there.

Turn on the motor

switch to start the projector running. Then turn on

the sync switch to

the "SYNC MOUSE" position.

The on-screen capture

button should begin "clicking" on its own.

After capture, review

the footage on regular television monitor to look for pulldown

blur. A computer monitor

should be avoided for critical review during this process

because computers

and macs will notoriously drop a field to accomodate

the display of interlaced

video. If you have pulldown blur that exists on a field

that is beind dropped,

you will not see it. But you will see it on regular interlaced

television monitor.

Pulldown blur is caused

because the film was captured during motion instead of

stationary in the

gate. Every camera/computer combination has a slightly different

timing characteristic

so there is no way for us to "pre-set" the timing.

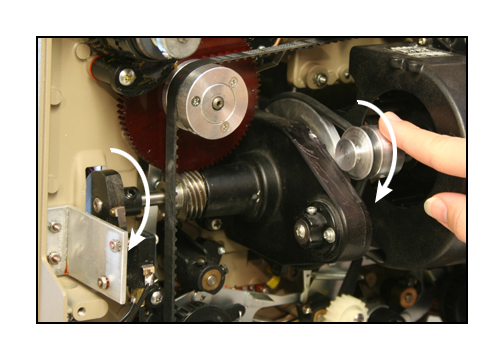

To adjust the timing,

remove the back cover by taking out the various screws

edge of the

cover. Near the front you will see a small timing disk.

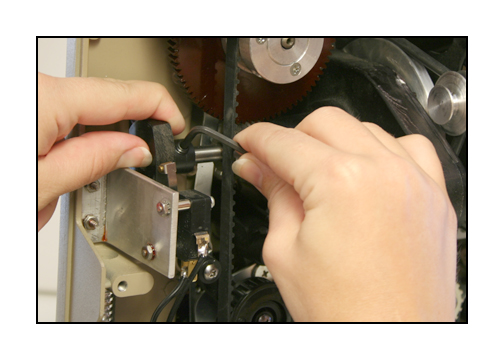

To get to the timing

disk set screw, you may need to rotate the motor pulley;

Loosen using a small

hex head wrench.

Once you loosen the

screw, turn the timing disk on the shaft to a new position.

Re-tighten the set

screw to hold the new position. Do not over-tighten

or you will crack

the plastic timing disk.

Repeat a capture and

then review the file to look for pulldown blur, etc.

If your timing is set

correctly, you will have no noticable pulldown blur.

If your timing is

set incorrectly, you will have blur that comes and goes randomly.

It is not unusual

to have to turn the timing disk almost 360 degrees from the

initial position.

Again, there is no "pre-set" position. Every set up is different.

As noted on the website,

your Mac or PC should have three drives. One drive should

be your system drive

and the other two should form a Raid-0 drive array. All should

be internal and no

external capture drives should be used. SATA drives should be

avoided for your Raid

for best results, if possible. Make sure that all other programs

are shut down during

the capture process. No screen savers, no minimized programs,

no active network

cards, etc.

Once you have your

timing set, you can then capture and process the files through

your software for

speed changes, etc or you can do it on your NLE afterwards.

If you need, you can

reduce the speed of the WorkPrinter by changing belt position.

To lower the speed,

remove the back cover and locate the motor drive pulley.

Use the same hex head

wrench to loosen the set screw.

Slide the pulley toward

the motor and move the belt

to the smaller groove.

Make sure the belt is straight and gently,

but firmly, tighten

the set screw.

Feel free to contact

me if you have any questions! 830-966-4664

Roger